要使驰放气发电机组生产达成标准,需要注意以下几个方面:

To achieve the production standards of the exhaust gas generator set, the following aspects need to be noted:

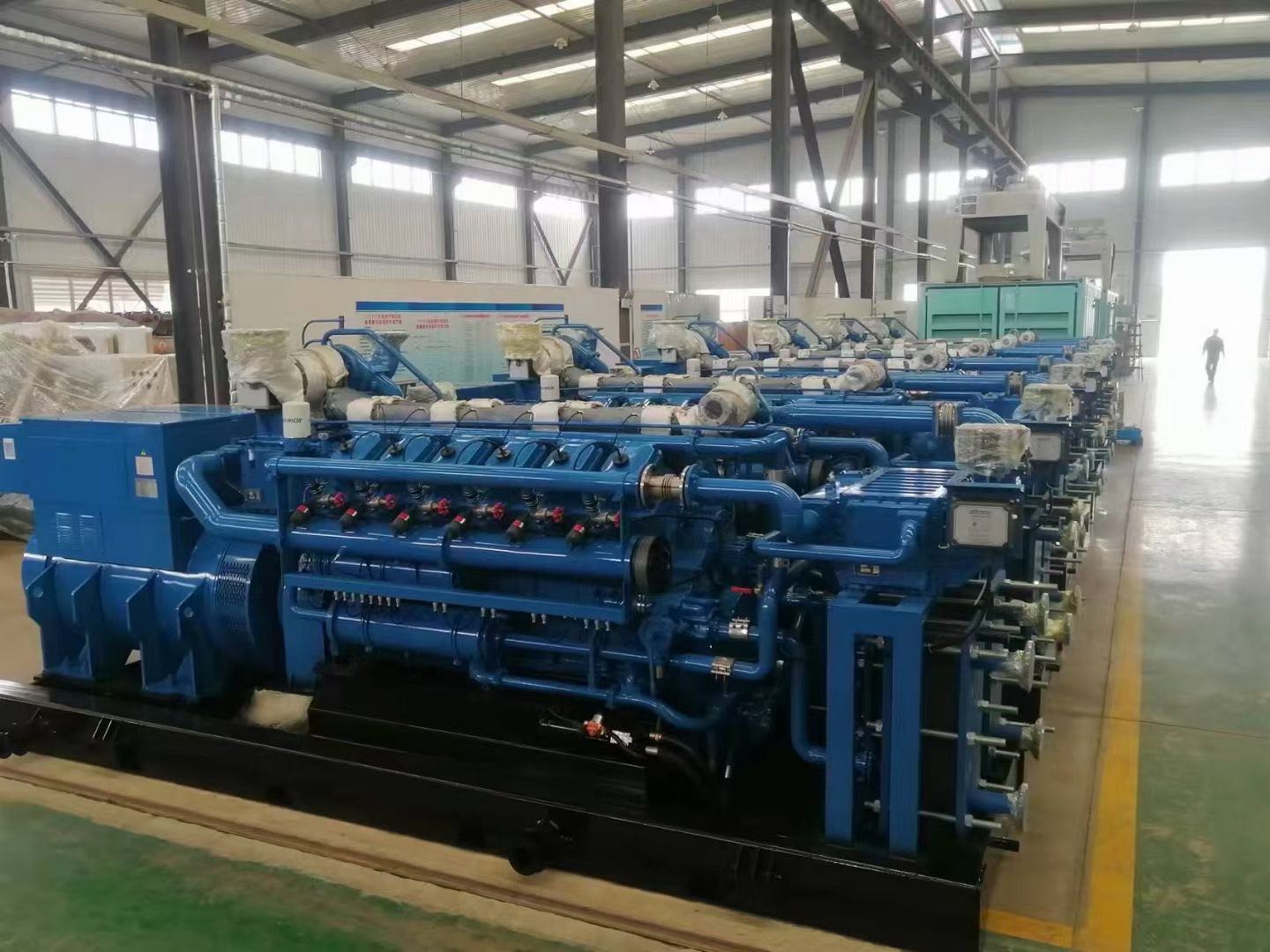

设备质量控制:确保所使用的驰放气发电机组设备符合相关的国家标准和技术规范,以及企业自身的质量管理体系。选择优质的供应商,并进行严格的设备检测和试验,确保设备的性能和可靠性符合要求。

Equipment quality control: Ensure that the used exhaust gas generator set equipment complies with relevant national standards and technical specifications, as well as the company's own quality management system. Select high-quality suppliers and conduct strict equipment testing and testing to ensure that the performance and reliability of the equipment meet the requirements.

生产工艺控制:建立科学、高效的生产工艺流程,确保每一道工序都能够有效地完成,并严格按照标准要求进行操作。对每个工序进行监控和检测,确保生产过程中不出现问题或质量缺陷。

Production process control: Establish a scientific and efficient production process to ensure that each process can be effectively completed and operated strictly in accordance with standard requirements. Monitor and inspect each process to ensure that there are no problems or quality defects during the production process.

品质管理:建立完善的质量管理体系,包括原材料采购、生产管理、产品检测等环节。通过对原材料进行严格把控,合理安排生产计划,加强产品检测和验证,确保生产出的驰放气发电机组符合标准要求。

Quality management: Establish a comprehensive quality management system, including raw material procurement, production management, product testing, and other links. By strictly controlling raw materials, arranging production plans reasonably, strengthening product testing and verification, we ensure that the produced exhaust gas generator sets meet the standard requirements.

员工培训和素质提升:对生产员工进行必要的培训和技能提升,确保他们具备足够的专业知识和技能,能够熟练操作设备和掌握相关的生产工艺。加强员工的质量意识培养,使其深入了解和执行质量管理要求。

Employee training and quality improvement: Provide necessary training and skill enhancement to production employees to ensure that they possess sufficient professional knowledge and skills, can proficiently operate equipment and master relevant production processes. Strengthen the cultivation of quality awareness among employees, so that they can deeply understand and implement quality management requirements.

过程监控和分析:建立合理的过程监控机制,对整个生产过程进行实时监控和数据分析。通过不断优化生产过程,发现并解决潜在的问题,确保生产达到标准要求。使用数据分析方法,对关键工序进行统计和分析,找出影响产品质量的关键因素,采取相应的措施进行改进。

Process monitoring and analysis: Establish a reasonable process monitoring mechanism to conduct real-time monitoring and data analysis of the entire production process. By continuously optimizing the production process, identifying and resolving potential problems, ensuring that production meets standard requirements. Use data analysis methods to conduct statistics and analysis on key processes, identify key factors that affect product quality, and take corresponding measures for improvement.

售后服务:提供完善的售后服务体系,及时处理用户反馈的问题和需求。对于设备使用中出现的故障或质量问题,及时派遣维修人员进行处理,并进行问题分析和改进措施的制定,以提高产品质量和用户满意度。

After sales service: Provide a comprehensive after-sales service system, and promptly handle user feedback issues and needs. For equipment failures or quality issues that occur during use, timely dispatch maintenance personnel to handle them, analyze the problems, and develop improvement measures to improve product quality and user satisfaction.

通过以上几个方面的注意和控制,可以使驰放气发电机组的生产达到标准,并提高产品质量和竞争力。。

By paying attention to and controlling the above aspects, the production of the exhaust gas generator set can meet the standards and improve product quality and competitiveness..

全国服务热线:

全国服务热线:

全国服务热线:

全国服务热线: 济南济柴环能燃气发电设备有限公司

济南济柴环能燃气发电设备有限公司