石油化工企业,在炼油过程中或其他生产过程中,会产生大量炼化尾气。这些尾气中大都含有氢气、一氧化碳、少量甲烷还有其他一些烃类等可燃成分,还含有一些二氧化碳、氮气、氧气等其他气体。有些炼钢、炼铁等工业企业,在生产过程中也产生大量工业尾气,气体成分和炼化尾气成分大体相同。

Petrochemical enterprises produce a large amount of refining tail gas during the refining process or other production processes. These exhaust gases mostly contain combustible components such as hydrogen, carbon monoxide, small amounts of methane, and other hydrocarbons, as well as other gases such as carbon dioxide, nitrogen, and oxygen. Some industrial enterprises such as steelmaking and ironmaking also produce a large amount of industrial exhaust gas during the production process, with the gas composition and refining exhaust gas composition being roughly the same.

炼化尾气(工业尾气)气体成分复杂,企业再利用度低,绝大部分都通过火炬烧掉,造成了环境污染和资源的严重浪费,在当今提倡环保和节约的社会形势下,成了一个亟待解决的问题。这些炼化尾气(工业尾气)因为含有大量的可以利用的可燃气体,可以通过内燃发电机组进行发电,既减少了尾气对环境的污染也给企业源源不断地提供了大量电力。

The composition of refining tail gas (industrial tail gas) is complex, and the reusability of enterprises is low. The vast majority of it is burned through torches, resulting in environmental pollution and serious waste of resources. In today's social situation that advocates environmental protection and conservation, it has become an urgent problem to be solved. These refining and chemical exhaust gases (industrial exhaust gases) contain a large amount of combustible gases that can be utilized for power generation through internal combustion power generation units, which not only reduces environmental pollution caused by exhaust gases but also provides a continuous supply of electricity to enterprises.

炼化尾气(工业尾气)主要成分:

Main components of refining tail gas (industrial tail gas):

因为不同的企业和不同的生产工艺,所产生的尾气成分相差较大,主要可利用的成分为氢气、一氧化碳、少量甲烷还有其他一些烃类等可燃成分,还含有一些二氧化碳、氮气、氧气等其他气体。该种尾气中氢气含量往往较高,这种气体特别适合燃气发电机组发电。

Due to different enterprises and production processes, the composition of the tail gas produced varies greatly. The main available components are hydrogen, carbon monoxide, a small amount of methane, and other combustible components such as hydrocarbons, as well as other gases such as carbon dioxide, nitrogen, oxygen, etc. The hydrogen content in this type of exhaust gas is often high, and this gas is particularly suitable for gas generator sets to generate electricity.

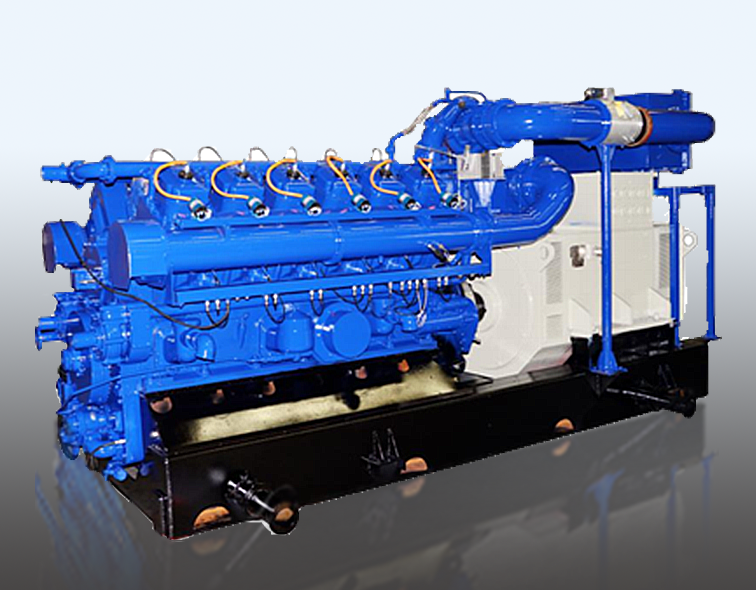

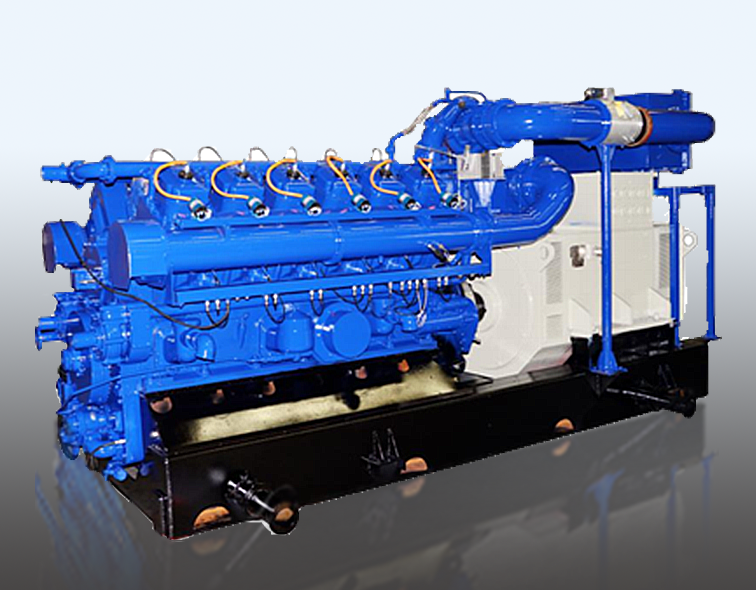

炼化尾气(工业尾气)发电机组优势:

Advantages of Refinery Tail Gas (Industrial Tail Gas) Generator Set:

1.炼化尾气发电机组具有缸径大、行程长、排量大的优点,适合低热值气体发电,能够确保机组输出功率持续恒定。

1. The refining tail gas generator unit has the advantages of large cylinder diameter, long stroke, and large displacement, suitable for low calorific value gas power generation, and can ensure continuous and constant output power of the unit.

2.机组采用内混式进气系统及空燃比自动控制系统,彻底避免了高氢燃气回火放炮问题。阻绝回火,确保燃气输送安全。

2. The unit adopts an internal mixing intake system and an air fuel ratio automatic control system, completely avoiding the problem of high hydrogen gas backfire and blasting. Prevent backfire and ensure safe gas transmission.

3.自然吸气,确保燃气输送安全,气源的压力只需大于 2kPa 即可,使燃气机组的适用范围更广,对燃气中焦油的适用性强,气源低压输送更安全。自吸式进气,气体混合后直接进入燃烧室,不需要涡轮增压器、中冷器等进气环节,部件少,自然减少了故障率。

3. Natural suction ensures the safety of gas transmission. The pressure of the gas source only needs to be greater than 2kPa, making the gas unit more suitable for tar in the gas and safer for low-pressure transmission of the gas source. Self priming intake allows the gas to mix and enter the combustion chamber directly, eliminating the need for intake components such as turbochargers and intercoolers. With fewer components, the failure rate is naturally reduced.

4.燃气机组点火系统采用美国或德国进口等点火系统,保证点火受控,确保获得高的点火能量和精确的点火时间,使做功更彻底,能量更大,爆发力更强。

4. The ignition system of the gas unit adopts ignition systems imported from the United States or Germany, ensuring controlled ignition, obtaining high ignition energy and precise ignition time, making work more thorough, energy greater, and explosive.

5.可拆卸进气阀箱,不需拆卸缸盖即可方便维护进气阀,清理焦油。

5. The detachable intake valve box allows for easy maintenance of the intake valve and cleaning of tar without disassembling the cylinder head.

6.低转速确保机组使用寿命,保证年运行8000h,大修周期60000h。

6. Low speed ensures the service life of the unit, ensuring an annual operation of 8000h and a maintenance cycle of 60000 hours.

7.机组可以手动、自动并机并网功能,亦可孤岛运行,可实现远程监控及操作等功能

7. The unit can have manual and automatic parallel and grid connection functions, as well as island operation, and can achieve remote monitoring and operation functions

全国服务热线:

全国服务热线:

全国服务热线:

全国服务热线: 济南济柴环能燃气发电设备有限公司

济南济柴环能燃气发电设备有限公司